At Xinda, we believe that by always providing products that meet or exceed your quality requirements, we earn your continued trust as a reliable partner for EMS. We use a rigorous quality management system (QMS) to control the entire production process to ensure the quality of each assembly level.

Utilizing our proprietary tracking system, Xinda operates a rigorous five-stage quality control system that includes:

1. IQC: Incoming Materials Inspection First Article Inspection for every process

2. IPQC: in-process quality control QC: 100% Test & Inspection

3. assembly complete function aging test

4. first article inspection

5. final inspection and out-of-box audits.

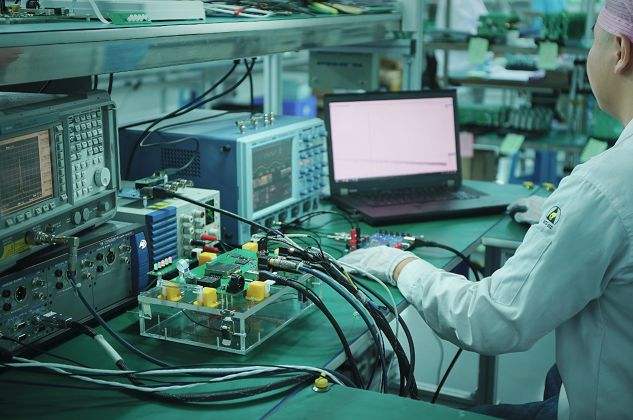

Regarding the function test, when customers send us the test file, we help them write IC, offer the possibility to integrate in-circuit testing, 100% functional testing, calibration/adjustment of the test object, parameter setting (e.g. an EEPROM), installing software (e.g. in FLASH), optoelectronic assembly control, high-voltage testing, and other technologies.